Flexible Printed Circuit (FPC) Comprehensive Catalog

A large number of flexible circuit boards that are thin and lightweight, making them excellent for space-saving solutions!

This catalog features a wide range of "Flexible Printed Circuits (FPC)" that our company handles. We offer products such as "High-Flex FPC," which demonstrates excellent bending performance even in narrow spaces, "Self-Supporting Sliding FPC," which can slide and bend while remaining upright in the air, and "Power FPC," which can handle high currents. 【Contents】 ■ FPC Product Concepts ■ Areas of Achievement ■ Process Overview ■ What is a Flexible Printed Circuit (FPC)? ■ Product Introduction *For more details, please refer to the PDF document or feel free to contact us.

- Company:沖電気工業 産業営業本部 産業営業統括室

- Price:Other

![[Example of Printed Circuit Board Manufacturing] Rigid-Flexible Board](https://image.mono.ipros.com/public/product/image/7c0/2001120580/IPROS81776454173382698581.png?w=280&h=280)

![Flexible printed circuit board "High Flex FPC" [Over 10 million bending cycles]](https://image.mono.ipros.com/public/product/image/d9f/2000259252/IPROS3622696248031507306.png?w=280&h=280)

![High Current Flexible Circuit Board [*FPC Technology Catalog Available]](https://image.mono.ipros.com/public/product/image/c7d/2000477292/IPROS51770483967615096271.png?w=280&h=280)

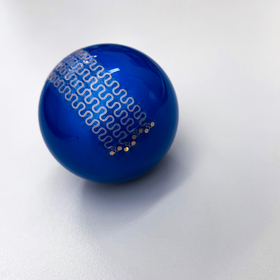

![[Design and Production Example] Coil_FPC for Motor Field Windings](https://image.mono.ipros.com/public/product/image/396/2000618456/IPROS87961089620937907596.png?w=280&h=280)